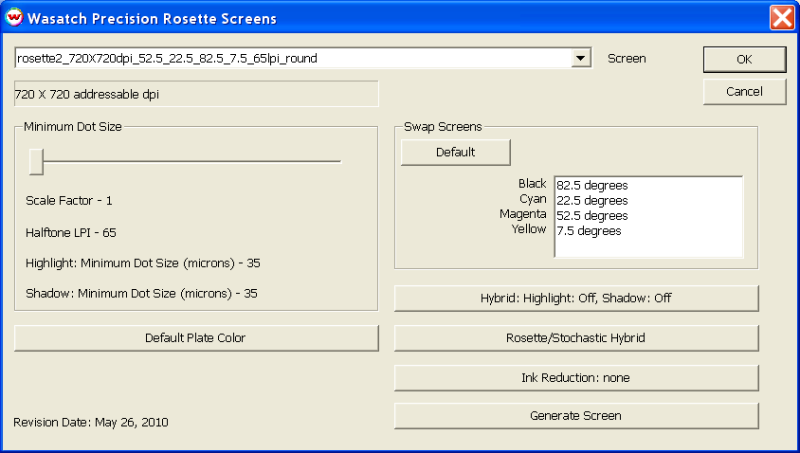

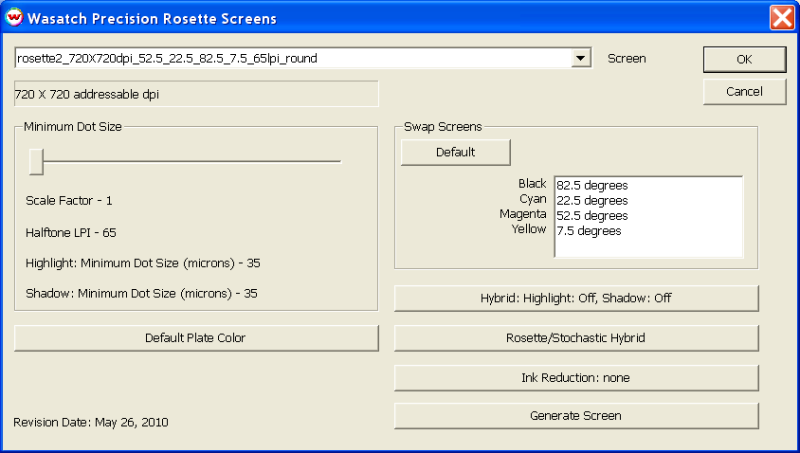

Quality process color printing calls for high-end screening that is free of the "rosette failure" problems typical of inexpensive RIP software.

Wasatch Precision Rosette Screens are the solution—screen sets that will produce center-filled rosettes across the full width of your wide format digital printer (Note: your final results also depend on the accuracy of registration of your printer and film and on additional moiré that may be introduced by the mechanics of your printer).

Wasatch Precision Rosette Screens are a standard component of SoftRIP SP for Separations Printing. They are not included in the basic Wasatch SoftRIP product.

Before you can use Wasatch Precision Rosette Screens, you must generate at least one screen. Do this by clicking on the "Generate Screen" button below. Read more about this here.

Your generated screen sets can be selected using the Screen drop-down menu. Wasatch Precision Rosette Screens will appear on this list beginning with the word "rosette", as shown in the illustration above. This information is followed by the horizontal and vertical device dpi for which the screen was created.

Ensure that the dpi for which the screen was created matches the "addressable dpi" shown in the field just below the list of screens. If these do not match, you will produce screens that are the wrong lpi, that are "squashed", or are otherwise incorrect. Note that the "addressable dpi" shown here may differ from the dpi indicated on the main Wasatch list of printers, which is the "equivalent" or "effective" dpi advertised by the printer manufacturer. In the illustration above, a dpi of 720X1440 has been correctly selected.

In the description of the rosette screen, the target device dpi is followed by the screen's lpi, and a code for the dot shape.

The Dot Size controls can be used to reduce lpi while producing a slightly more jagged dot. This can be used to print with lpi values lower than those that can be directly generated by Wasatch Precison Rosette Screens, and to do so with larger minimum dot sizes. Note that another powerful way to control minimum dot sizes is through the use of Hybrid screens.

Read about the Swap Screens control in the Moiré section of online help. Also read our note about specifying Screen Angles in SoftRIP.

If a monochrome page (plate) is sent to the RIP, and that plate does not specify its color as Cyan, Magenta, Yellow, or Black, the plate will be printed with screen angles for the color specified on the button for Default Plate Color. This button is grayed out in non-monochrome print modes.

Read more about Hybrid screening here.

Read more about this powerful tool for elimination of moiré here.

Successful production of separation films often requires careful adjustment between the amount of ink needed for sufficient density and the limitations of the film's ability to accept ink. This tool is powerful for "tuning in" good compromises.

Wasatch Precision Rosette Screens are based on sophisticated "threshold arrays", which can take several minutes to compute. This control allows these computations to be done in advance, for re-use in production. See a more detailed description here.

As important as this capability is for high-end process color printing, not everybody needs it. For example, it isn't really needed at all for spot color. Even for process color, some "lower end" printing may not be sensitive to the moiré problems that these screens solve.

Here's a way to judge whether you need Wasatch Precision Rosette Screens, or whether your needs can be met with the PostScript screens included with the basic Wasatch SoftRIP package.

|  |

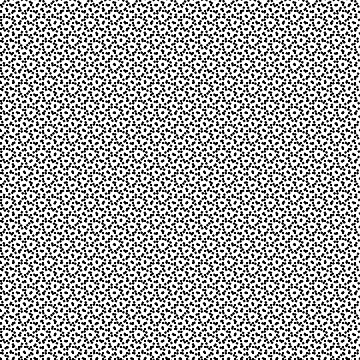

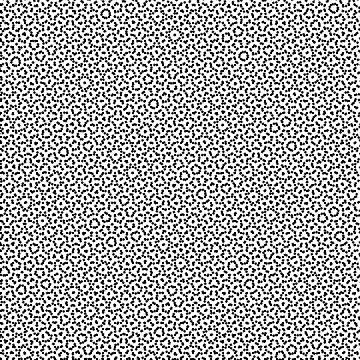

The "Failed CMK Rosette" above illustrates the problem that arises when process separations are slightly out of register. This problem nearly always arises with digital halftones of less quality than Wasatch Precision Rosette Screens.

One way to test is by making separation films of a test image that really shows the problem. A good choice is an image that prints a large area of a solid light gray using all four inks. We commonly use a test pattern consisting of a 10X10 inch square with 15% each of C, M, Y, and K. A suitable file for this purpose is available for download at the Wasatch web site.

To make such a test, turn off all linearizations and color configurations in your RIP, print a set of four films from this file, tape the CMK films onto a light box, and look for the failure of the CMK rosette. Use a screen of about 55lpi or 65lpi to make it easy to see.

With Wasatch Precision Rosette Screens and accurately registered films, you'll see no failure at all. Instead, you'll see something resembling the "CMK Rosette" illustration above.

With any lesser screening method, such as the PostScript Screens in Wasatch SoftRIP, you'll nearly always see the kind of problem illustrated in "Failed CMK Rosette" above.

The question of whether you need Wasatch Precision Rosette Screens is simply the question of whether or not you care about this moiré.